Types of Work Involved

-

Brickwork

-

Cladding

-

Demolition

-

Fencing

-

Flooring

-

Groundwork & Civil Engineering

-

Painting & Decorating

-

Sanitaryware Install & Plumbing

-

Structural Engineering

The Project

Our client was moving premises a short distance and had an external plant which required moving as well as new services which required connection. The works incorporated the installation of a new gas compound, pipe bridge, perimeter fencing, and block paving. The works were to be designed and installed in line with client specifications and approval.

The existing two large gas tanks in a fenced-off compound were situated in the car park of the old premises and these had to be re-sited to the new premises.

Due to the site being a live production site, the works had to take place while the clients’ personnel were on site and in several phases so as not to impact production. Works were programmed to the client’s wishes and planned accordingly.

The position of the gas tanks was a good distance from the service exit point of the building. Once the tanks and adjacent temporary buildings had been removed, the walling and floor had to be tidied and made attractive and useable. A new perimeter fence was also required to maintain security. The works had to be carried out giving the clients staff safe access into the building by Youngman boarding over rough terrain from fence line to plant room doors.

The new base had to be installed with new tanks and piped system all commissioned and filled before the existing system could be isolated and drained off. This would ensure no impact on product processing. The base had to be broken with minimal vibration due to a very sensitive plant room adjacent.

The first phase was to excavate and form the new base foundation for the new gas storage tanks. The bases were designed and calculated for the intended use and installed to specification. Once completed the client arranged to have the Gas storage vessels installed.

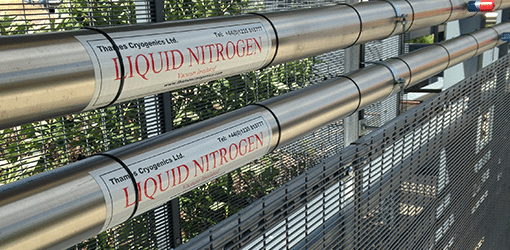

The next phase was the fabrication and installation of the new pipe bridge. The pipe bridge was fabricated off-site and installed onsite. Excavations were made with pre-calculated load-bearing concrete bases installed and the columns were bolted into the bases. The bridge was then assembled and painted with metallic oil-based paint. Whilst the gas pipework was installed

and commissioned, we installed the perimeter fence. All fencing was of a prison mesh construction and powder coated to match pipe bridge. The cladding was then installed to the outside of the pipe bridge at the client’s landlord’s request to shield the pipework and pipe bridge from general view. Once all the pipework had been signed off we then installed Uni-Strut to the bridge and prison mesh to protect all pipework.

The third phase was the removal of the temporary packing building and timber link to the production building. This work was tied in with the clients’ programme to meet the exact timeline of the completion of their new packing department, so the old building had to be demolished in a weekend so as not to affect their production.

The portable cabin was carefully disengaged from the temporary timber link building and moved to one of the clients other sites where we could carry out dilapidation of it, in readiness for it to be returned to the supplier.

The link building was carefully removed from the production building and disposed of. This work involved isolation and removal of electrical and fire alarm services and demolition of the structure along with making good of brickwork and fascia’s to the production building.

The fourth and final phase incorporated civil engineering works including demolition of the existing gas storage tank, compound fencing and base foundations. The solution for reducing vibration when removing the base was done by cutting the slab into many smaller pieces then lifting out into an adjacent skip. Large amounts of spoil had to be removed and all waste was recycled.

This phase included the installation of several hundred square metres of block paved surfaces to the North and Western perimeter and the installation of the perimeter prison mesh fencing to define the boundary of the clients land. This phase was problematic for various reasons and had to be planned in a way to not compromise any of the fire escape routes.

The finished job gives a pleasing finish throughout. Practical, easy to use, safe and secure.